At VBG Intech we offer a complex variety of packing options, yet keeping it simple to identify the right selection for your application.

VBG Intech has two primary product ranges of packing.

- BlueSeal

Standard Packing Systems, for non-hazardous applications that may not require 500 ppmV or less leakage.

- GreenSeal

Fugitive Emission Packing Systems, for hazardous control valve applications that require restricted emissions levels below 500 ppmV.

VBG Intech’s BG-S & BG-H Series Control Valve packing box is deep and has excellent surface finish, allowing the use of all packing options offered by Valtek Sulamericana.

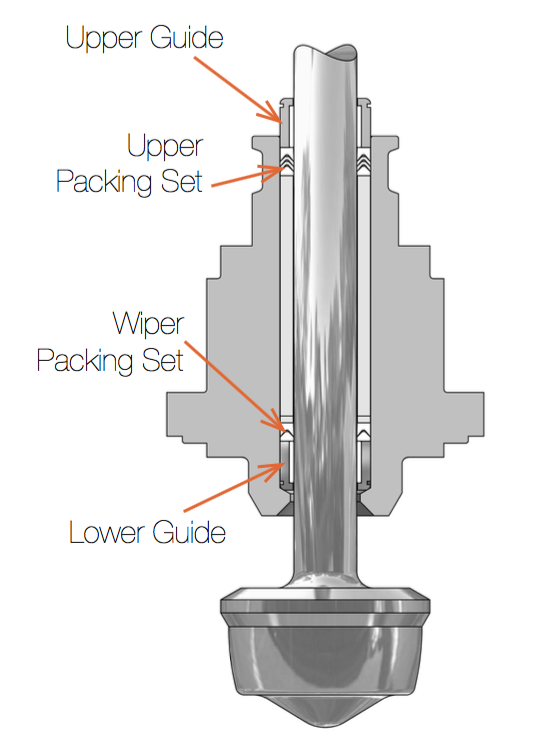

The spacing between the lower wiper packing set and the upper packing set, which is effectively responsible for stem sealing, is designed to restrict the wetted portion of the plug stem from reaching the upper packing set.

The packing eliminates problems caused by friction and wear, usually associated with control valves that have the guide system based in the seat retainer (cage-guided).

Valtek Sulamericana’s Control Valves are unique in having two large and widely spaced guides (located out of the flow path) and a plug stem with a large diameter that comprise the advanced guiding system of the Valtek Sulamericana GLS & GLH Series Control Valves.

The upper guide also works as a packing gland, while the lower guide, located next to the plug head, assures a sturdy alignment between the plug and the seat ring.

The available guide options cover all the applications of Valtek Sulamericana Control Valves.

Guiding

Temperature and Pressure Limits for Plug Guides and Inserts

| Guide/Insert Material | Temperature Limit | Pressure Limit |

|---|---|---|

| Stainless Steel with Graphite Insert 1, 2 | —196 to 815°C 3 | Up to 1,000 psi (69.0 Bar) for sizes up to 2″. Upto 600 psi (41.4 Bar) for sizes 3″ and 4″ |

| Stainless Steel with PTFEG Insert | —28 to 150°C | 850 psi (58.6 Bar) @ 38°C; 100 psi (6.9 Bar) @ 150°C |

| Bronze (Solid Guide)4 | —253 to 260°C5 | Body Rating |

Alloy #6 (Solid Guide)6

| —253 to 815°C |

Body Rating |

|

1The ΔP through the valve must be observed for each valve size, therefore recommended to consult factory.

2Do not use in Oxygen enriched services. In applications experiencing cavitation conditions, the use of a graphite insert at the lower guide is not recommended.

3For oxidizing services such as air, the maximum operating temperature is 426°C.

4Bronze solid guides should not be used in corrosive applications or when NACE compliance is required.

5For the upper guide, the maximum temperature limit is 483°C. 6Whenever a valve trim is of a 300 series Stainless Steel, and the lower guide is made from Alloy #6, the plug stem must be hardened with Alloy #6, in the stem region that is in contact with the lower guide.

BlueSeal Packing

VBG Intech recommends the BlueSeal Packing Series for non-hazardous applications, in which leakage classes below 500 ppmV are not required. The BlueSeal range of packing is not designed for Fugitive Emissions control, for that VBG Intech offers the GreenSeal Packing.

BlueSeal

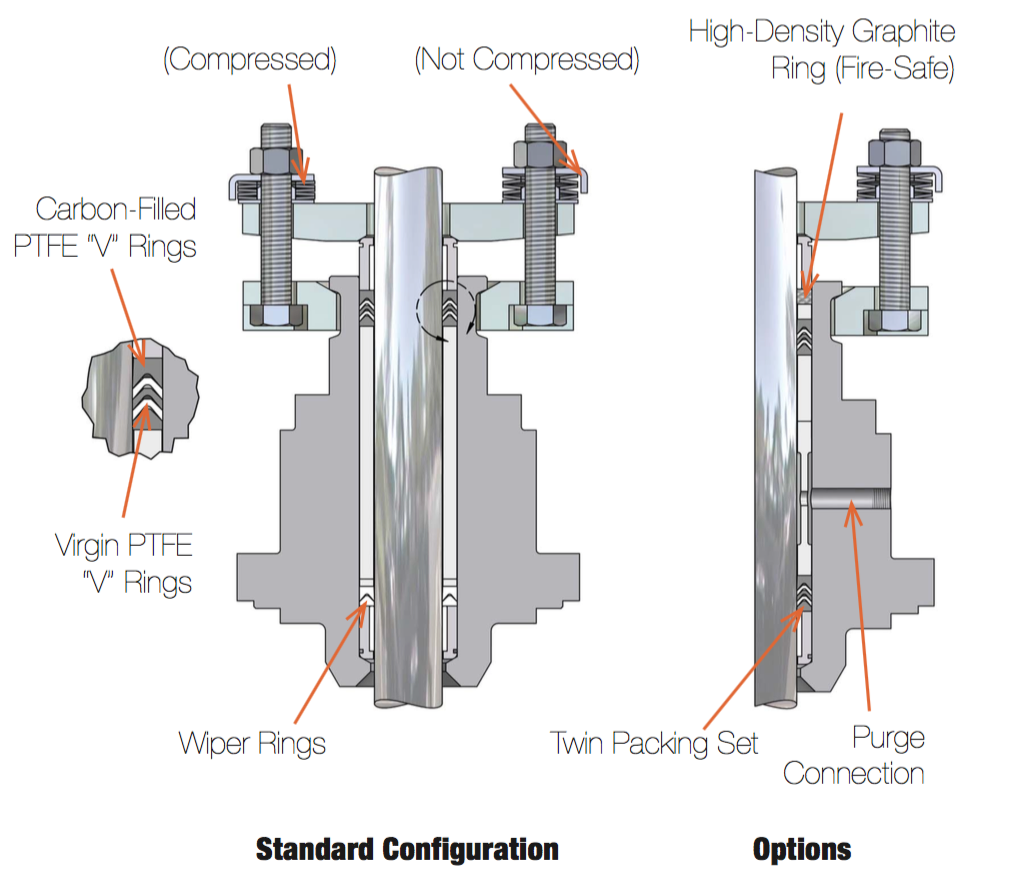

The basic packing offered by VBG Intech, composed of a double top guided system. Using virgin PTFE “V-Rings”, the Blueseal packing caters to a wide range of general service applications. The BlueSeal packing system is offered for use with standard, extended and cryogenic bonnets, as well as in single (illustrated in image on right) or twin packing configurations.

BlueSeal Packing Temperature Limits

| Model | Type | Specification | Standard | Extended | Cryogenic |

|---|---|---|---|---|---|

| BlueSeal | V-Ring | Virgin PTFE V-Ring | −28°C to 232°C | −100°C to 316°C | |

| BlueSeal with 15 or 18in. extention | V-Ring | Virgin PTFE V-Ring | −196°C | ||

| BlueSeal with 24 or 27in. extension | V-Ring | Virgin PTFE V-Ring | -253°C |

GreenSeal Packing

VBG Intech recommends the GreenSeal Packing Series for hazardous fugitive emission control applications, in which leakage classes below 50 ppmV are required. VBG Intech offers four main types of packings under the GreenSeal Series and are the GreenSeal, GreenSeal Plus, GreenSeal Extra, and GreenSeal SuperMax. The GreenSeal range of packing is designed for Fugitive Emissions control.

GreenSeal

VBG Intech’s GreenSeal Packing is a live loaded fugitive emission control packing that ensure emissions levels are maintained lower than 500 ppm.

The GreenSeal Packing is composed of virgin PTFE V-Rings combined with carbon—filled PTFE V-Rings that are compressed by means of Belleville washers set that create a “live load” effect, and is available for the majority of control valves manufactured by VBG Intech.

Designed with simplicity in mind, VBG Intech’s GreenSeal packing is easy to replace and maintain, as the system being live loaded, it avoids the need for retightening, due to pressure and temperature variations in the process.

GreenSeal Packing Temperature Limits

| Model | Type | Specification | Standard | Extended | Cryogenic |

|---|---|---|---|---|---|

| GreenSeal—LS | V-Ring | Virgin PTFE V-Ring + Carbon Filled PTFE, Live Loading, Single | −100°C to 316°C | ||

| GreenSeal—LT | V-Ring | Virgin PTFE V-Ring + Carbon Filled PTFE, Live Loading, Twin | −100°C to 316°C |

GreenSeal Plus

VBG intech’s GreenSeal Plus Packing is a fugitive emission control packing that comprises of alternate V-Rings of Kalrez®1 perfluoroelastomer (FFKM) and V-Rings of Teflon®1 PTFE, to form a highly effective control valve packing set for fugitive emission control.

The GreenSeal Plus Packing Sets by VBG Intech are widely used to minimize fugitive emissions at oil, gas, petrochemical and chemical processing plants, and can typically reduce valve stem leakage to less than 10ppm.

Prime Features

- Very low friction when lubricated correctly.

- Kalrez® V-rings energise under axial load to form a highly efficient fluid seal.

- Rigid back-up rings of Teflon® limit the extrusion of Kalrez® elements.

Chemical Properties

All GreenSeal Plus components display outstanding chemical resistance. They are inert to media in the range pH 0-14.

1 Registered Trademark of DuPont

GreenSeal Plus Packing Temperature Limits

| Model | Type | Specification | Standard | Extended | Cryogenic |

|---|---|---|---|---|---|

| GreenSeal Plus—S | V-Ring | Kalrez + PTFE Filled, Single | −100°C to 316°C | ||

| GreenSeal Plus—LS | V-Ring | Kalrez + PTFE Filled, Live Loading, Single | −100°C to 316°C | ||

| GreenSeal Plus—T | V-Ring | Kalrez + PTFE Filled, Twin | −100°C to 316°C | ||

| GreenSeal Plus—LT | V-Ring | Kalrez + PTFE Filled, Live Loading, Twin | −28°C to 232°C |

GreenSeal Extra

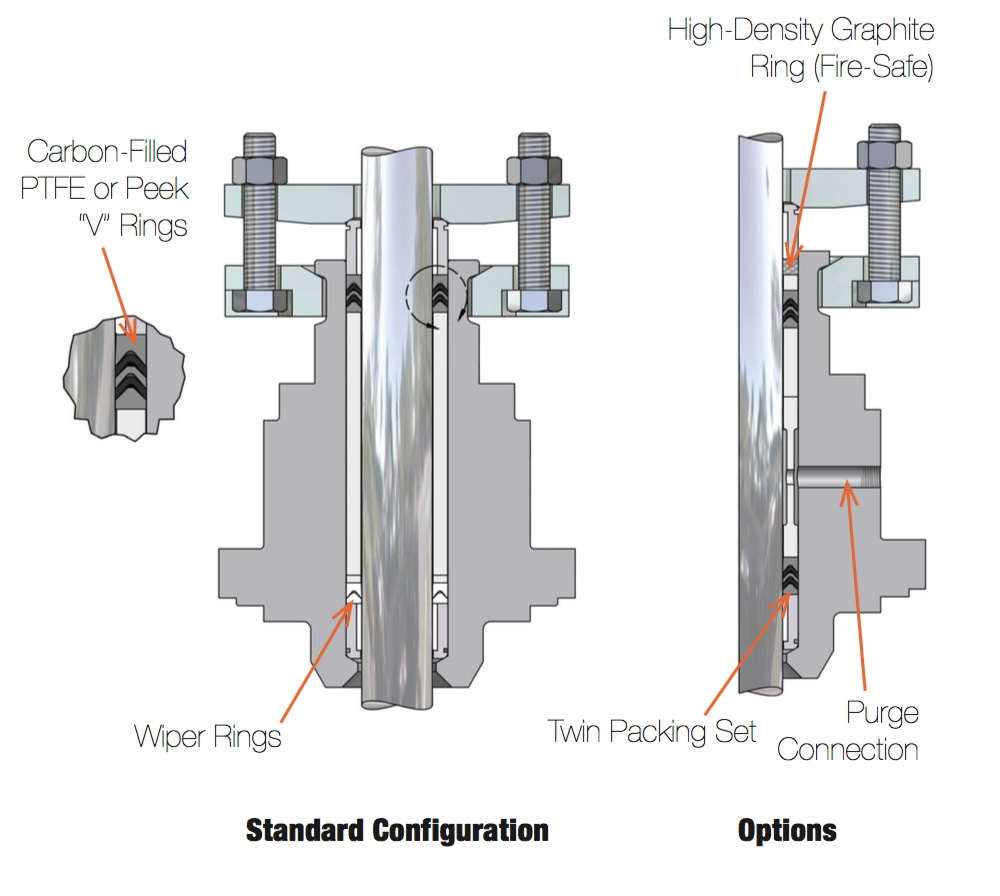

VBG Intech’s GreenSeal Extra Packing is a high temperature version of the GreenSeal Plus. It is a fugitive emission control packing that comprises of alternate V-Rings of Kalrez®1 perfluoroelastomer (FFKM) and V-Rings of Zymaxx® — a composite of carbon fibre and PFA Teflon®, to form a highly effective control valve packing set for fugitive emission control.

The GreenSeal Extra Packing Sets by VBG Intech are widely used to minimize fugitive emissions at oil, gas, petrochemical and chemical processing plants, and can typically reduce valve stem leakage to less than 10ppm.

Prime Features

Very low friction when lubricated correctly.

Kalrez® V-rings energise under axial load to form a highly efficient fluid seal.

Rigid back-up rings of Teflon® limit the extrusion of Kalrez® elements.

Chemical Properties

All GreenSeal Plus components display outstanding chemical resistance. They are inert to media in the range pH 0-14.

1 Registered Trademark of DuPont

GreenSeal Extra Packing Temperature Limits

| Model | Type | Specification | Standard | Extended | Cryogenic |

|---|---|---|---|---|---|

| GreenSeal Extra—S | V-Ring | Zymax + Kalrez, Single | −28°C to 371°C | ||

| GreenSeal Extra—S | V-Ring | Zymax + Kalrez, Live Loading, Single | −28°C to 371°C | ||

| GreenSeal Extra—T | V-Ring | Zymax + Kalrez, Twin | −28°C to 371°C | ||

| GreenSeal Extra—LT | V-Ring | Zymax + Kalrez, Live Loading, Twin | −28°C to 371°C |

GreenSeal SuperMax

VBG Intech’s GreenSeal SuperMax Control Valve Packing is an innovative compression packing that provides long-term, high integrity sealing for BG Series control valves. Its very low friction enhances the control accuracy of control valves.

The GreenSeal SuperMax packing is manufactured in exfoliated graphite, reinforced with a non-metallic structure to provide additional strength and resistance to pressure and extrusion. An advanced lubricant system is incorporated to prevent the pick up of graphite on the Control Valve stem.

VBG Intech has designed the GreenSeal SuperMax packing for environmental fugitive emission control to better than 50 ppm leak tightness on control valves handling fluid media such as hydrocarbon liquid fuels and gases, lubricating oils and hazardous process chemicals.

The GreenSeal SuperMax can be also used as a long term replacement to VBG Intech’s BlueSeal Packing (PTFE V-Rings).

VBG Intech BG Series Control Valves fitted with the GreenSeal SuperMax packing are certified to ISO 15848-1 Class BH, CC3, at temperatures from −29°C to +425°C. The valves showed helium leakage rates less than 10-4 mg.s-1 for 100,000 stem operating cycles.

Prime Features

- High integrity gland sealing for BG Series Control Valve Stems to well below 50ppm fugitive emission levels.

- Long term adjustment free operation; over 100,000 stem cycles with emission levels below 500ppm.

- Very low coefficient of friction for smooth and accurate valve action.

- Reduced friction requirement to save on power consumption and enable smaller actuators to be used.

GreenSeal SuperMax Packing Temperature Limits

| Model | Type | Specification | Standard | Extended | Cryogenic | GreenSeal SuperMax—S | Braided | Exfoliated Reinforced Graphite, Single | −200°C to 350°C |

|---|---|---|---|---|---|

| GreenSeal SuperMax —LS | Braided | Exfoliated Reinforced Graphite, Single, Live Loaded | |||

| GreenSeal SuperMax—T | Braided | Exfoliated Reinforced Graphite, Twin | −200°C to 350°C | ||

| GreenSeal SuperMax —LT | Braided | Exfoliated Reinforced Graphite, Twin, Live Loaded |